产品中心 / Product center

|

|

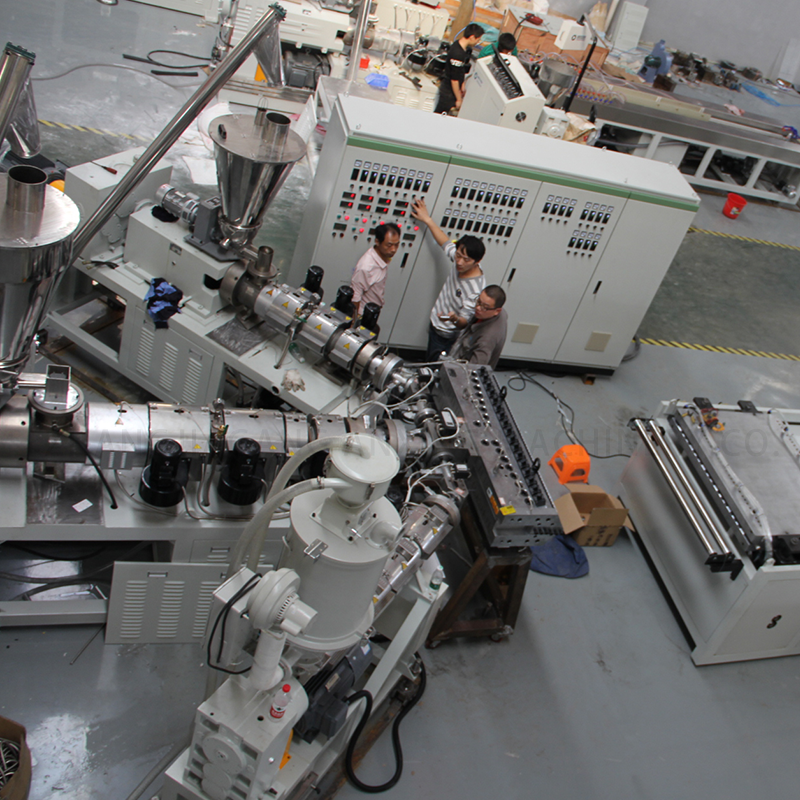

UPVC/PVC Corrugated/Waved Roofing Tiles/Sheets Production Machinery

Collect

Introduction for PVC roofing sheet making machine PVC Resin Roofing Sheet Tiles Extrusion Making Machine is manufactured based on 3 layer co-extrusion technology by one-time processing. It is an ideal building material for construction projects with heat insulation requirement. The following is a list of the distinct features of each layer material.

1.World famous brand inverter--ABB, stable and reliable. 2.World famous brand contactor--Schneider, reliable performance. 3.World famous brand temperature controller--Omron, precision temperature control, reliable and durable. 4.Automatically low power consumption: minimum total production line consumption is 25kw/hour. 5. Economical price, which is suitable for large scale investment. Overseas exhbition from Anxing machinery

Welcome to contact us for details

|